FLAT JACKS – LIFTING BAGS

& LOW HEIGHT CYLINDERS

HYDRAULIC JACKS • HYDRAULIC CYLINDERS • PUMPS • SYNCHRONOUS LIFTING SYSTEMS

RENTALS • SALES • SERVICE

Freyssi Flat Jacks: Small Tools with Big Impact in Structural Engineering

In the world of construction, infrastructure maintenance, and structural engineering, few devices combine compact design with sheer power quite like the Freyssi Flat Jack. Distributed in the United States by WB Equipment, these innovative tools play an essential role in projects ranging from bridge rehabilitation to the stabilization of historic buildings. Slim enough to fit into tight spaces yet strong enough to apply immense loads, Freyssi Flat Jacks have earned a reputation as indispensable problem-solvers across multiple industries.

Freyssi Flat Jack

Freyssi

Low Height Jacks

Enerpac

Air Lifting Bags

Simplex

Ultra Flat Cylinder

Enerpac

Common Applications

Because of their versatility, Freyssi Flat Jacks are used in many different scenarios, including:

Preloading and prestressing beams, joints, and other structural elements.

Transferring loads in bridge bearings during maintenance or replacement.

Lifting or realigning structures in confined work zones.

Applying controlled forces in laboratory tests and structural mock-ups.

Repairing and stabilizing concrete in tunnels, dams, and other large infrastructure.

Typically, the jack is inserted into the space between two structural members. Hydraulic pressure is applied gradually, ensuring even distribution of force. Once the desired adjustment is reached, steel plates are inserted as permanent supports before depressurizing the jack.

Essential Accessories

For optimal performance, Freyssi Flat Jacks are typically used with:

Hydraulic pumps (hand-operated or powered) to generate pressure.

Pressure gauges for precise monitoring.

Steel shims or packers for locking loads in place.

Flexible hoses to allow use in hard-to-reach areas.

Protective housings when long-term or embedded installation is required.

WB Equipment supplies these accessories as part of a complete system, ensuring contractors have everything needed for reliable operation.

Who Uses Them in the USA?

Across the United States, Freyssi Flat Jacks serve a variety of industries:

Civil Construction – for bridge bearing replacement, column alignment, and wall stabilization.

Transportation Infrastructure – including rail and highway systems requiring support adjustments.

Power and Energy – from hydroelectric dams to nuclear facilities, where structural integrity is critical.

Mining and Tunneling – for controlled lifting and support in confined underground spaces.

Marine and Offshore – in foundation maintenance and subsea structures.

Historical Preservation – to carefully stabilize and reposition fragile architectural elements.

Advantages and Interesting Facts

The concept of the Flat Jack was pioneered by Eugène Freyssinet, a trailblazer in prestressed concrete technology.

Their thin profile allows them to be embedded directly into concrete and permanently grouted into place.

They provide highly accurate pressure control, making them safe for sensitive applications.

Multiple jacks can be operated simultaneously for balanced load distribution.

Custom sizes are available, and WB Equipment often supplies specialized versions for unique engineering challenges.

Flat Jack

Freyssi

Flat Jack

Freyssi

Flat Jack

Freyssi

Flat Jack

Freyssi

Enerpac Low-Height Hydraulic Cylinders:

Maximum Power in Minimal Space

What They Are

Enerpac’s line of low-profile hydraulic cylinders—also known as hydraulic pancake jacks—are designed for jobs requiring high force in extremely tight vertical clearances. Models include:

CUSP Series: Single-acting, spring return

CULP Series: Lock nut load-holding design

LPL Series: Extra-low profile for extreme constraints

Key Specs:

Rated for 10,000 psi (700 bar)

Feature Nitrocarburized coating for corrosion protection

Comply with ASME B30.1 standards (except BRD-RD-Series)

Where and How They’re Used

These cylinders are ideal for:

Bridge bearing replacements

Steel mill maintenance

Heavy machinery positioning

Power plant infrastructure projects

Their compact design makes them invaluable in applications where standard jacks simply won’t fit.

Accessories Needed

Hydraulic pump (manual, electric, or air-powered)

High-pressure hoses and couplers

Pressure relief valves

Synchronization controls (for multi-jack lifts)

Industries in the U.S.

Construction and civil engineering

Energy sector (nuclear, hydro, wind)

Shipbuilding and aerospace

Heavy equipment maintenance

Interesting Fact:

Despite their small height (as little as 1.5 inches), Enerpac flat cylinders can lift over 100 tons, making them true powerhouses in tight quarters.

RSM Low Height

Enerpac

LPL Low Height

Enerpac

CUSP Ultra Flat

Enerpac

CULP Flat Cylinder

Enerpac

Common Applications

Because of their versatility, Freyssi Flat Jacks are used in many different scenarios, including:

Preloading and prestressing beams, joints, and other structural elements.

Transferring loads in bridge bearings during maintenance or replacement.

Lifting or realigning structures in confined work zones.

Applying controlled forces in laboratory tests and structural mock-ups.

Repairing and stabilizing concrete in tunnels, dams, and other large infrastructure.

Typically, the jack is inserted into the space between two structural members. Hydraulic pressure is applied gradually, ensuring even distribution of force. Once the desired adjustment is reached, steel plates are inserted as permanent supports before depressurizing the jack.

Essential Accessories

For optimal performance, Freyssi Flat Jacks are typically used with:

Hydraulic pumps (hand-operated or powered) to generate pressure.

Pressure gauges for precise monitoring.

Steel shims or packers for locking loads in place.

Flexible hoses to allow use in hard-to-reach areas.

Protective housings when long-term or embedded installation is required.

WB Equipment supplies these accessories as part of a complete system, ensuring contractors have everything needed for reliable operation.

Who Uses Them in the USA?

Across the United States, Freyssi Flat Jacks serve a variety of industries:

Civil Construction – for bridge bearing replacement, column alignment, and wall stabilization.

Transportation Infrastructure – including rail and highway systems requiring support adjustments.

Power and Energy – from hydroelectric dams to nuclear facilities, where structural integrity is critical.

Mining and Tunneling – for controlled lifting and support in confined underground spaces.

Marine and Offshore – in foundation maintenance and subsea structures.

Historical Preservation – to carefully stabilize and reposition fragile architectural elements.

Advantages and Interesting Facts

The concept of the Flat Jack was pioneered by Eugène Freyssinet, a trailblazer in prestressed concrete technology.

Their thin profile allows them to be embedded directly into concrete and permanently grouted into place.

They provide highly accurate pressure control, making them safe for sensitive applications.

Multiple jacks can be operated simultaneously for balanced load distribution.

Custom sizes are available, and WB Equipment often supplies specialized versions for unique engineering challenges.

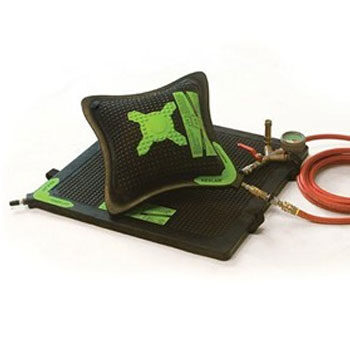

Lifting Bags

Simplex

Lifting Bags

Simplex

Lifting Bags

Simplex

Lifting Bags

Simplex

Closing Thoughts

Freyssi Flat Jacks may not look imposing at first glance, but their ability to deliver precision force in tight spaces makes them vital across countless structural applications. With the support of WB Equipment, industries in the U.S. have access to these versatile hydraulic tools along with the pumps, gauges, and accessories needed to put them to work. Whether stabilizing a bridge, adjusting a tunnel lining, or preserving a landmark building, Freyssi Flat Jacks prove that sometimes the most compact tools make the biggest difference.